Factory source Black Silicone Glue - Two-component board glue – DESAY

Factory source Black Silicone Glue - Two-component board glue – DESAY Detail:

5. Usage:

(1) Pretreatment: base material leveling, glue, according to the proportion of the main agent (milky white) and curing agent (dark brown) 10:1 ratio.Stir the glue evenly, and the mixed glue should be used up within 30 ~ 60 minutes.

(2) sizing: sizing should be completed in 1 minute, the cloth glue is uniform and the end cloth glue should be sufficient.

(3) composite: pressure time to be sufficient, the coated plate in 1 minute, 3 minutes must be pressurized, pressure time 45 ~ 120 minutes, special hardwood 2 ~ 4 hours.Pressure strength should be enough, cork 500 ~ 1000kg/m2, hardwood 800 ~ 15000kg/m2.

(4) Post-treatment: after pressure relief to keep healthy, health temperature above 20℃, 24 hours can be lightly processed (saw, planer), 72 hours after the deep processing, during the period to avoid sunlight and rain wet.

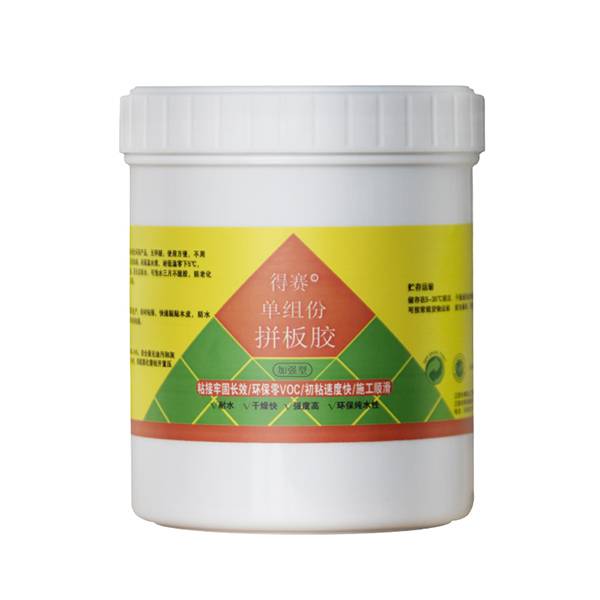

Product name: two-component plywood adhesive

Type of PVAC – PB

Capacity multiple specifications

The exterior color is milky white

Curing 50%

Brands have to match

Viscosity (MPa ·s) 5000-8000

PH 5-6

Curing time 2-4 hours

Shelf life is 12 months

Product parameters

| product name | Two-component board glue | Brand name | desay |

| type | PVAC-PB | Viscosity(MPA.S) | 5000-8000 |

| Specifications | 1L、5KG、10KG、25KG、50KG | PH | 5-6 |

| Exterior color | Main agent (Ivory)Hardener (light brown) | Curing time | 2-4h |

| Solid content | Main agent(≥50%)Hardener(≥99%) | Shelf life | 12 months |

Features

1、Strong adhesion

2、Excellent water resistance

3、Stable in nature

Scope of application

It is suitable for jigsaw bonding of non-structural materials and structural materials.

|

|

Instructions

1、Pretreatment: The moisture content of the wood should be controlled between 8-12%; the bonding base surface should be smooth and flat, without warpage, dust, oil, etc.

2、Sizing: the main agent: curing agent (10: 1) ratio mixing needs to fully stir for 3-5 minutes, until uniform. After the glue is prepared, it should be used up within 1-2 hours. Bubbles and volume expansion may occur during use, which is a normal phenomenon. You can continue to use after slight stirring.

3、Curing: The pressing time is generally 2-4 hours, depending on the temperature

and humidity of the construction environment.

Precautions

1.Base material leveling is key:

Flatness standard: ± 0.1mm Water content standard: 8% -12%;

2. The proportion of glue is very important:

The main agent (white) and curing agent (dark brown) are mixed at a ratio of 100: 10 according to the corresponding ratio;

3. Stir the glue evenly:

Use a stirrer to repeatedly pick up the colloid 3-5 times, without the filamentous brown liquid. The mixed glue solution should be used up within 30-60 minutes;

4. The glue application speed is fast and accurate:

The glue application should be completed within 1 minute. The glue should be uniform and the glue on the end should be sufficient.

5.Pressure time should be sufficient

The coated boards are pressed together within 1 minute, and must be pressurized within 3 minutes. The pressing time is 45-120 minutes, and the hardwood is 2-4 hours;

6, the pressure should be sufficient:

Pressure: softwood 500-1000kg / ㎡ hardwood 800-15000kg / ㎡;

7, after decompression to maintain health:

The health temperature is above 20 ° C, it can be lightly processed (saw, planed) in 24 hours, and can be further processed in 72 hours. Avoid sunlight and rain during the period;

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Factory source Black Silicone Glue - Two-component board glue – DESAY , The product will supply to all over the world, such as: Anguilla, Bahrain, Melbourne, We've got a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will absolutely benefit in both short and long run.

This supplier stick to the principle of "Quality first, Honesty as base", it is absolutely to be trust.