China Factory for Thermoplastic Epoxy Resin - Polyurethane adhesive glue – DESAY

China Factory for Thermoplastic Epoxy Resin - Polyurethane adhesive glue – DESAY Detail:

5. Usage:

(1) pretreatment: the surface of the adhesive is cleaned.

(2) sizing: use sawtooth scraper to apply the glue on the surface of the adhesive evenly, also can use mechanical rolling coating, can not use brush brush (glue viscosity is large), brushing amount of about 250g/m2, specific according to the actual situation control the amount of glue.

(3) composite: after the glue can be composite adhesive.

(4) post-treatment: because this glue is a foaming adhesive, when the adhesive layer is cured, the glue can be drilled into the micro hole of the adhesive, play the role of anchorage, increase the bonding strength, and must be compressed after curing.

Product parameters:

Product name polyurethane foaming adhesive

Brands have to match

Type of PU – 90

Viscosity (MPa ·s) 3000-4000

Capacity multiple specifications

PH 6-7

Appearance color is brown

Curing time 60 minutes

Curing 90%

Shelf life is 12 months

Polyurethane foam

Product parameters

| product name | Polyurethane adhesive | Brand name | desay |

| type | PU | Viscosity(MPA.S) | 6000-8000 |

| Specifications | 0.125L、0.5L、1.3KG、5KG、10KG、25KG | Curing time | 0.5-1h |

| Exterior color | brown | Shelf life | 12 months |

| Solid content | 65% |

Packaging specifications

Features

It has the characteristics of superior performance, convenient construction, foaming after curing, insolubility and insolubility, high and low temperature resistance.

Scope of application

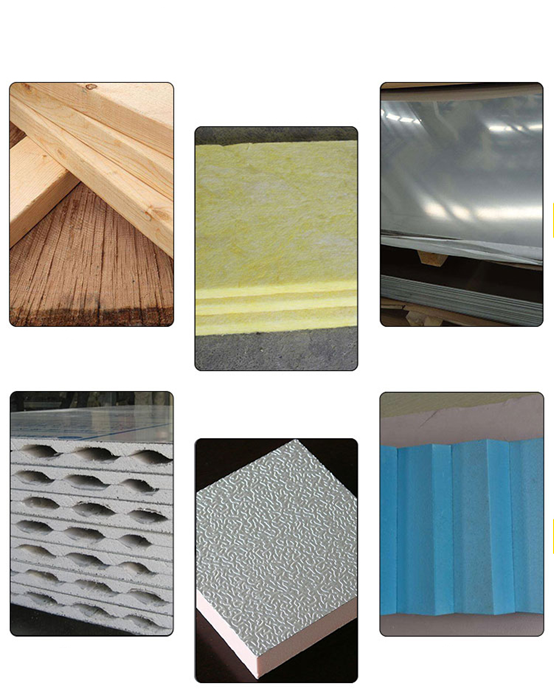

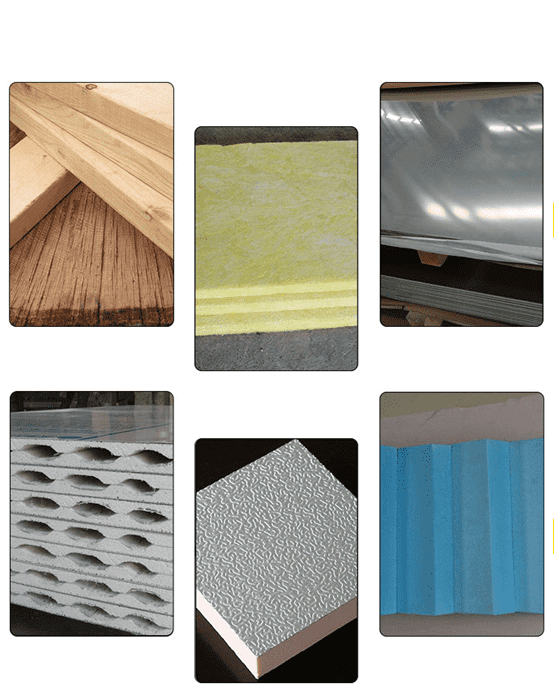

Manufacture of fire-resistant doors, anti-theft doors, household doors, cold equipment, and various fire-resistant and thermal insulation materials (rock wool, ceramic wool, ultra-fine glass wool, polystyrene foam plastic, etc.) are also used for bonding. For metal to metal adhesion.

Instructions

1. Principle of curing: This adhesive is a one-component solvent-free adhesive, which is cured by moisture absorbed in the air and on the surface of the adherend.

2.Surface treatment of the adherend: remove the oil and dust on the surface of the adherend. Excessive oil stains can be cleaned with acetone or xylene. If there is no oil stain, it is not necessary to clean. Time, if necessary, spray a small amount of water mist on the rubber surface with a sprayer.

3.Glue coating: Use a zigzag scraper to evenly apply glue on the surface of the adherend. Mechanical glue can also be applied, but brushing is not required (grease viscosity is large), and the coating amount is about 150-250g / ㎡. The surface of the adherend can be slightly reduced, and the surface roughness can be slightly increased, that is, as long as the surfaces of the two adherends meet and can fully contact the glue, the less the coating amount, the better, because the more glue is applied, the more The moisture absorbed on the surface of the adherend is limited, which will affect the curing time. If the amount of glue applied is required, a small amount of water mist can be sprayed appropriately.

4.compound: can be glued

5.Post-treatment: Due to the foaming adhesive of this rubber, when the adhesive layer is cured, the glue can drill down the micropores of the adherend, which plays an anchoring role and increases the bonding strength. The material is compacted and can be loosened after curing (the pressure is about 0.5kg-1kg / cm2).

6.Tool cleaning can use ethyl acetate solvent.

Precautions

1、Use a serrated spatula for the scraper, such as a flat plate. However, if the glue is applied too hard, there will be no glue left on the coating surface. If the glue is applied too lightly, the glue will be too much waste. The zigzag scraper is just as hard as it is, and the glue left by the sawtooth is as much.

2、The two bonding surfaces to be compounded must be glued on one side.

storage method

This product should be stored in a cool and dark place during storage. Generally in indoor warehouses, the storage period is one year. After each use of glue, the barrel with excess glue should be sealed and stored, and the upper layer of glue liquid will solidify and crust due to moisture intrusion. If it is not used for a long time, it should be sealed with nitrogen.

Product detail pictures:

Related Product Guide:

With state-of-the-art technologies and facilities, strict good quality regulate, reasonable cost, exceptional assistance and close co-operation with prospects, we're devoted to supplying the top benefit for our customers for China Factory for Thermoplastic Epoxy Resin - Polyurethane adhesive glue – DESAY , The product will supply to all over the world, such as: Sri Lanka, Mexico, Honduras, With a state-of-the-art comprehensive marketing feedback system and 300 skilled workers' hard work, our company has developed all kinds of products ranging from high class, medium class to low class. This whole selection of fine products offers our customers different choices. Besides, our company sticks to high quality and reasonable price, and we also offer good OEM services to many famous brands.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.